One Platform. One Pass. Many Solutions.

RailPod provides a complete suite of analyses and services in a single inspection using its equipment platform. This reduces costs by cutting mobilization, daily, and hourly labor expenses, while also minimizing track time since one RailPod captures all data. All information is displayed on a unified platform, and even if specific services aren’t listed below, RailPod can leverage its data and sensors to tailor deliverables that address your unique challenges and meet project goals.

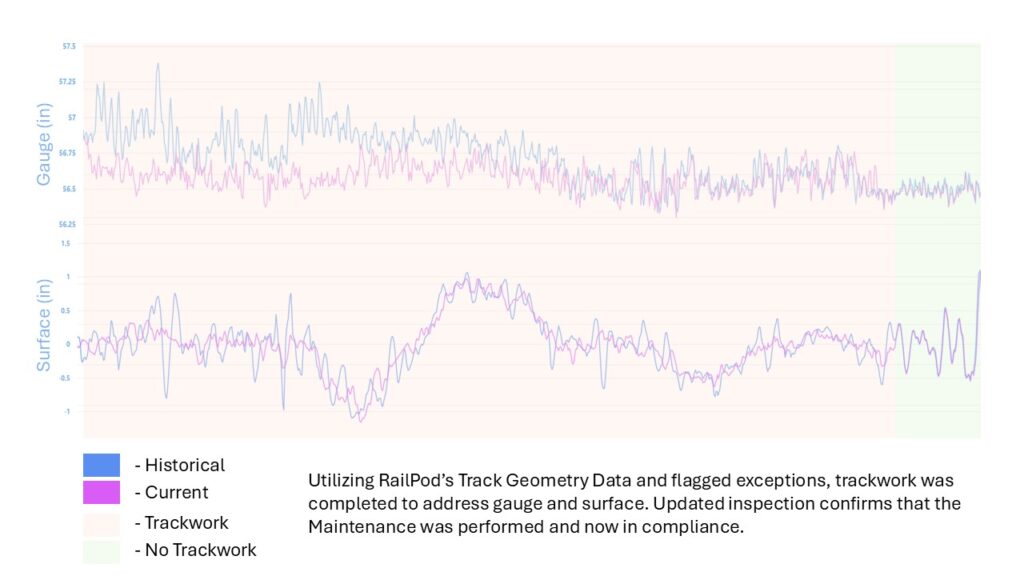

Track Geometry

A full complement of geometry measurements including gauge, cross level, alignment, surface, speed, warp, twist, curvature and elevation are displayed in brush charts and functional, user-friendly displays with imagery and GPS locations.

Exceptions are generated, classified, and evaluated in accordance with clients’ Maintenance of Way Standards. Exceptions are validated in real-time through RailPod’s Shadow Operations Team and the customer can receive text messages or emails when a defect occurs. The message includes a link to the defect location (latitude, longitude) as well as the description of the defects, chainage, severity, and type of defect.

The customer may review historical exceptions against the most current exceptions (i.e. run-on-run analysis) both in tabular and graphical form.

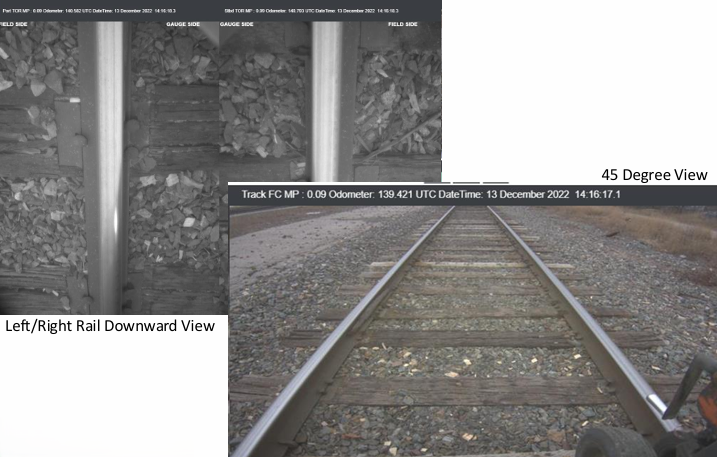

Images of various aspects of the track provide valuable insight for assessing a defect identifying visible defects, tie and ballast condition, and other indicators.

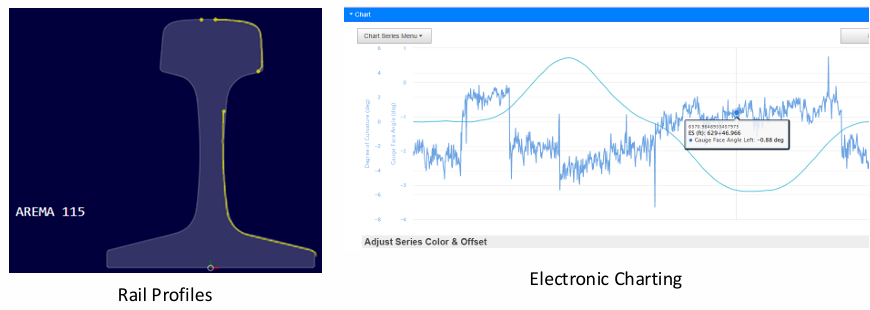

Rail Profiles

Measures horizontal wear, vertical wear, gauge face angle, rail cant, and rail size/type. Customers are able to compare differences in rail wear measurements over time with run-on-run comparisons.

Tabulated data organizes rail wear by tangents, curves, and rail type, helping prioritize low- or high-rail replacements and maintenance on critical curves

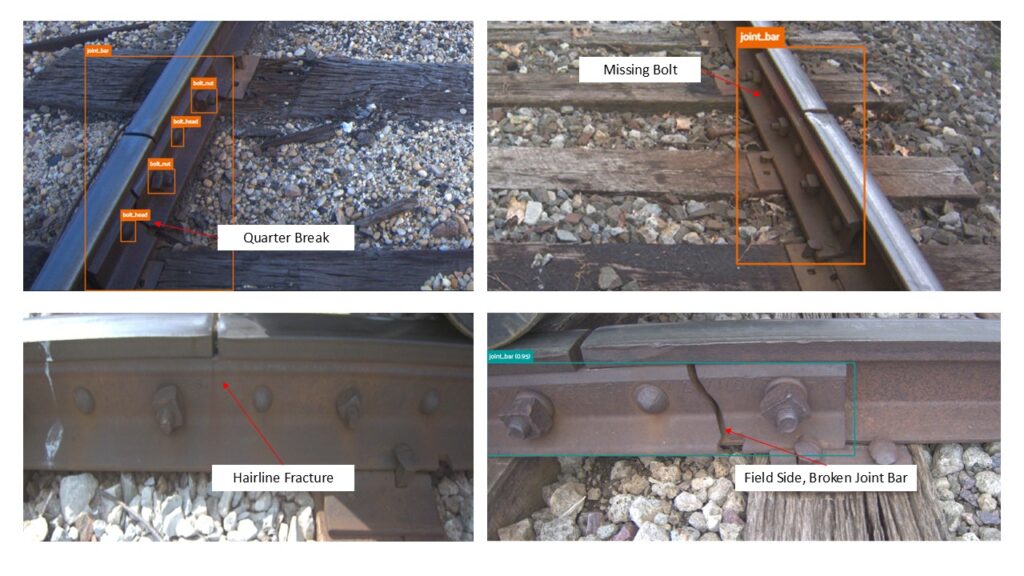

Joint Bars

Using images of the gauge and field sides of joint bars, RailPod’s Image Processing algorithm detects each joint bar and assesses its condition. Reports provide joint bar quantity and location, identify broken bars (quarter or center breaks), missing bolts, bolt patterns, and joint bar sizes. When processed with Rail Profiles, the type(s) of rail at the joint bar will be identified.

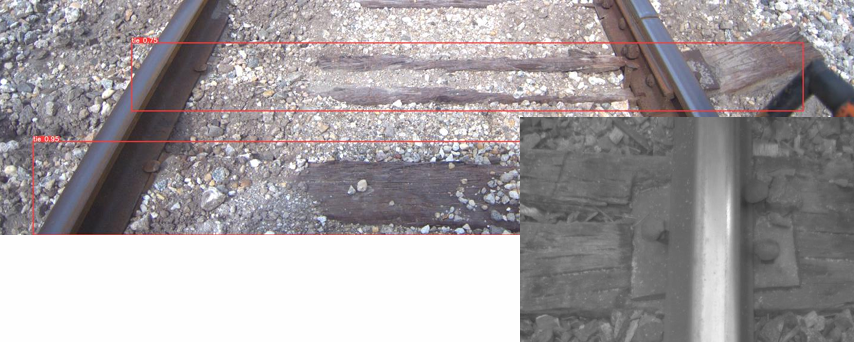

Ties

Using images of the track, RailPod’s Image Processing algorithm detects ties and assesses its condition. Reports provide individual tie assessments with a Good/Bad ranking on an adjustable sliding scale, including the quantity and location of all ties, identification of consecutive ‘bad’ ties, and defective ties by mile. The sliding scale can be customized to align with tie programs, priorities, or budgets.

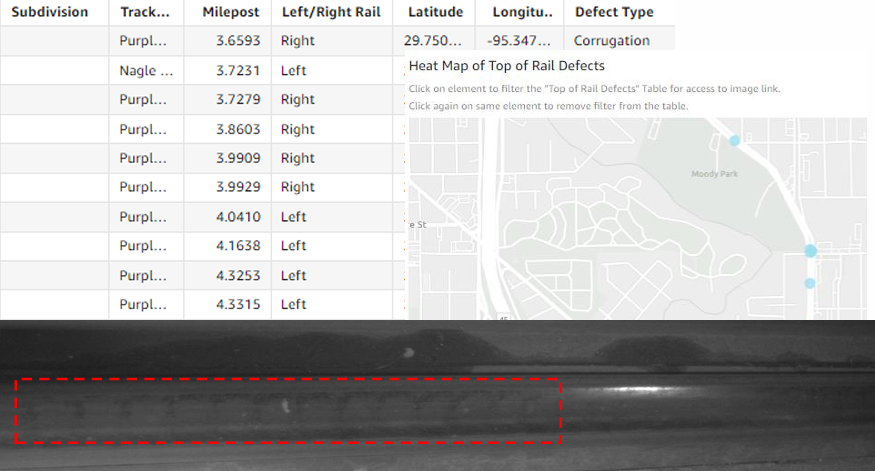

Top of Rail

RailPod will identify differences between corrugation, spalling, flaking, wheel burn, etc. Map depiction of the locations and density of rail condition. Individual images of top of rail defects linked directly from the above tables

Grooved Rail

To be released.

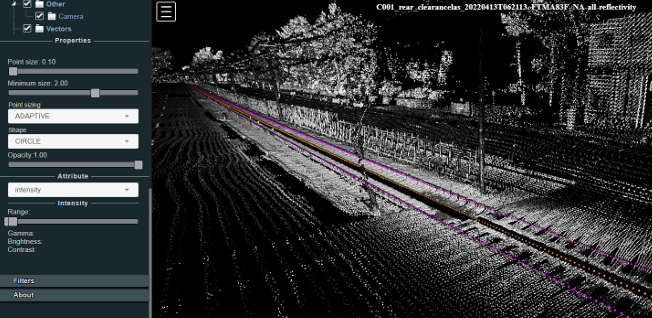

360 Degree LiDAR

Non-Survey Grade LiDAR Data & Viewer: Integrated 3D web-based viewer allowing measurements to be taken within each LiDAR file. LiDAR files are typically segmented into 500-meter intervals and can be downloaded in LAS format.

Left/Right/Center Vector Extraction: Left Rail, Center line, and Right rail are automatically extracted from the LiDAR data using the RailPod processing solution. These files can be extracted into DXF format for use in various CAD programs.

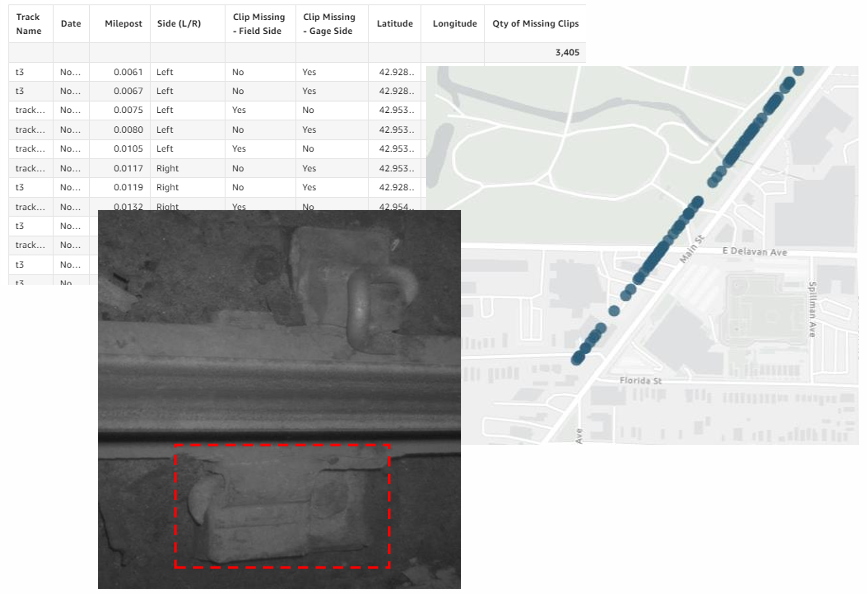

Fasteners

Includes identification of ties where clips are missing or broken, map depiction of the locations and density of missing fasteners, total number of clips/fasteners across railroad segment, and individual images of clips linked directly from the above tables.

Ballast

Report provides identification of areas where ballast is fouled (dirt, water, etc.), high, low, or obstructed. Also includes length of defective areas by milepost with GPS locations and links to imagery.

Gauge Rods

Report provides a tabular listing of gauge rods and associated pictures with location to include the line, direction, milepost/engineering station, latitude/longitude.

Tie Anchors

Report provides a tabular listing of tie anchors and associated pictures with location to include the line, direction, milepost/engineering station, latitude/longitude.

Overhead Catenary Height/Stagger

RailPod will work with the client to extract height/stagger criteria. Will then provide the user with the ability to measure height/stagger in relationship to track centerline and observe any overhang as the car enters a curve. Detects where the catenary wire exceeds the design or maintenance standards.

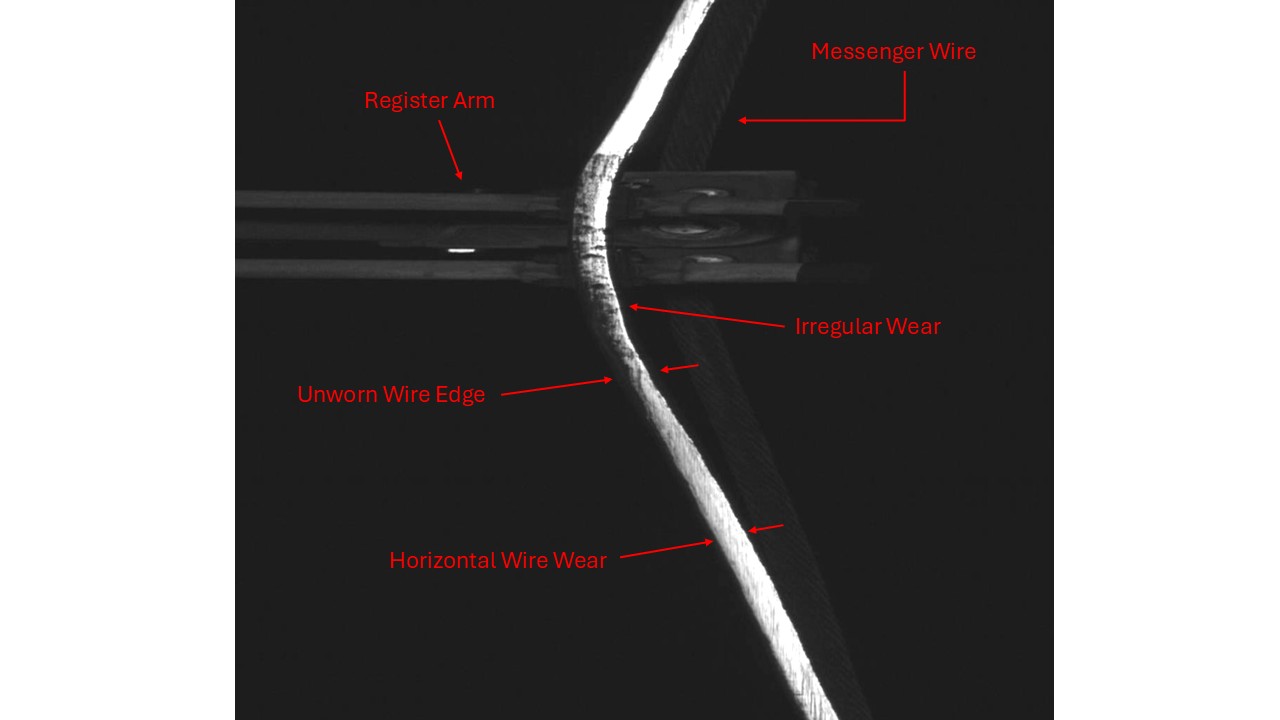

Overhead Catenary Wire Wear

OCS Wire Wear provides precise, non-contact measurements of overhead catenary systems using the RailPod, with no vehicle installation required. Its advanced imaging and detection algorithms capture high-resolution images of every inch of wire, clearly visualizing asset condition and detecting wear. The system measures wire height, stagger, wear width, remaining thickness, and overall condition, while also identifying poles, hangers, clamps, and other assets. Reporting includes actionable defect lists, predictive wear analysis for maintenance planning, and GIS-compatible data exports for asset management.

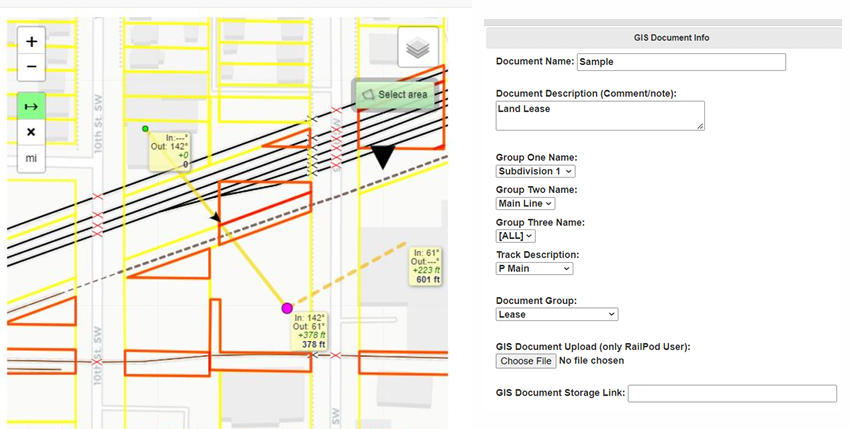

GIS/Asset Mapping

Capable of collecting survey grade GIS Spatial data to include GIS location of track center-line, track elevation, sign posts, switch location, bridges, tunnels, and other assets. Includes tools to add assets manually, update property boundaries, and measure distances along any two points within the system.

Virtual Track Walks

RailPod captures Forward and Downward facing images along the right of way to ensure every tie, joint, and rail surface is imaged. Users of the data portal can download images or conduct virtual track walks via the web-based software minimizing time on the tracks. General condition of ties, road condition, fasteners, ballast, etc. and defects can be reviewed from these images.

Engineering Services

The following are samples of work conducted by RailPod for different customers. Additional detailed engineering work can be completed to meet the demands of a variety of different customers.

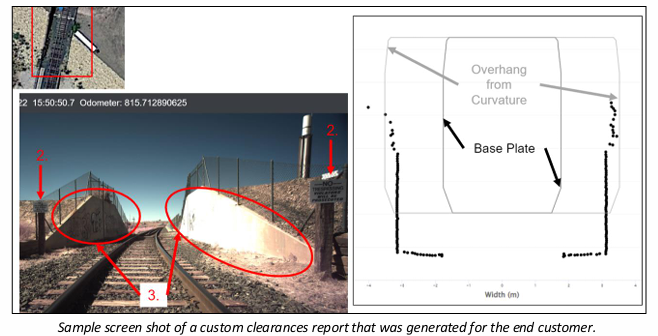

Clearance Studies

Initial Clearance Setup: RailPod will work with client to ingest custom rail car boundaries (i.e. limits/extents) and enter into the system for analysis. This may include different variants of rail cars, custom high-wide loads, etc. that are used throughout the system.

2D Profiles: Provides the user with the ability to measure right-of-way clearances in relationship to track centerline and observe car overhang (e.g. swing radius) as the car enters a curve.

Automated Defects: Defects where the car profile exceeds/encroaches upon wayside structures (e.g. stations, signs, etc.) or vegetation (low trees, etc.).

Other: GPS, Milepost, Engineering Station location with “hot link” to Google Maps for rapid identification of the defect.

Custom Reports: Custom reports quoted separately to illustrate a specific clearance assessment.

Road Crossing Surveys

One Pass: Regardless of inspection requirements, this data is collected and can be post processed into road crossing survey reports

360 Degree LiDAR: LiDAR extends from track centerline to capture clearances, wires, signs, etc. for accurate 2D and 3D drawings

Rapid Response: Collected data can be rapidly processed for detailed survey reports

Can simplify the process for Section 130 crossing upgrade grants. RailPod crossing surveys are far more detailed than conventional or Google Earth methods in locating and mapping existing infrastructure, equipment, utilities, vegetation, etc.

Post Construction Ballast Assessments

Post Construction Surveys to assess ballast/dirt volumes: Quickly assess ballast and dirt work volumes/quantities using the RailPod LiDAR and geometry system. Compare “as-built” to “Design” to control project costs. This feature is priced/quoted on a project specific basis and requires detailed conversations with engineers to properly define the engineering requirements, design requirements, etc.

Track Re-alignment and Throw Tables

Track Re-alignment: RailPod provides detailed track engineering and track re-alignment efforts based on customer specific needs. Information can be directly ported into tampers for simplified re-alignment operations.

Uniform Alignment

Post-processed Uniform Alignment: Identifies alignment deviations based on “uniform” curve of actual track condition, analyzing inflection points, spiral rates, and average DoC, minimizing exceptions and streamlining validation and maintenance. Particularly valuable for transit systems with high spiral rates and short curves, where real time alignment calculations tend to be exaggerated.